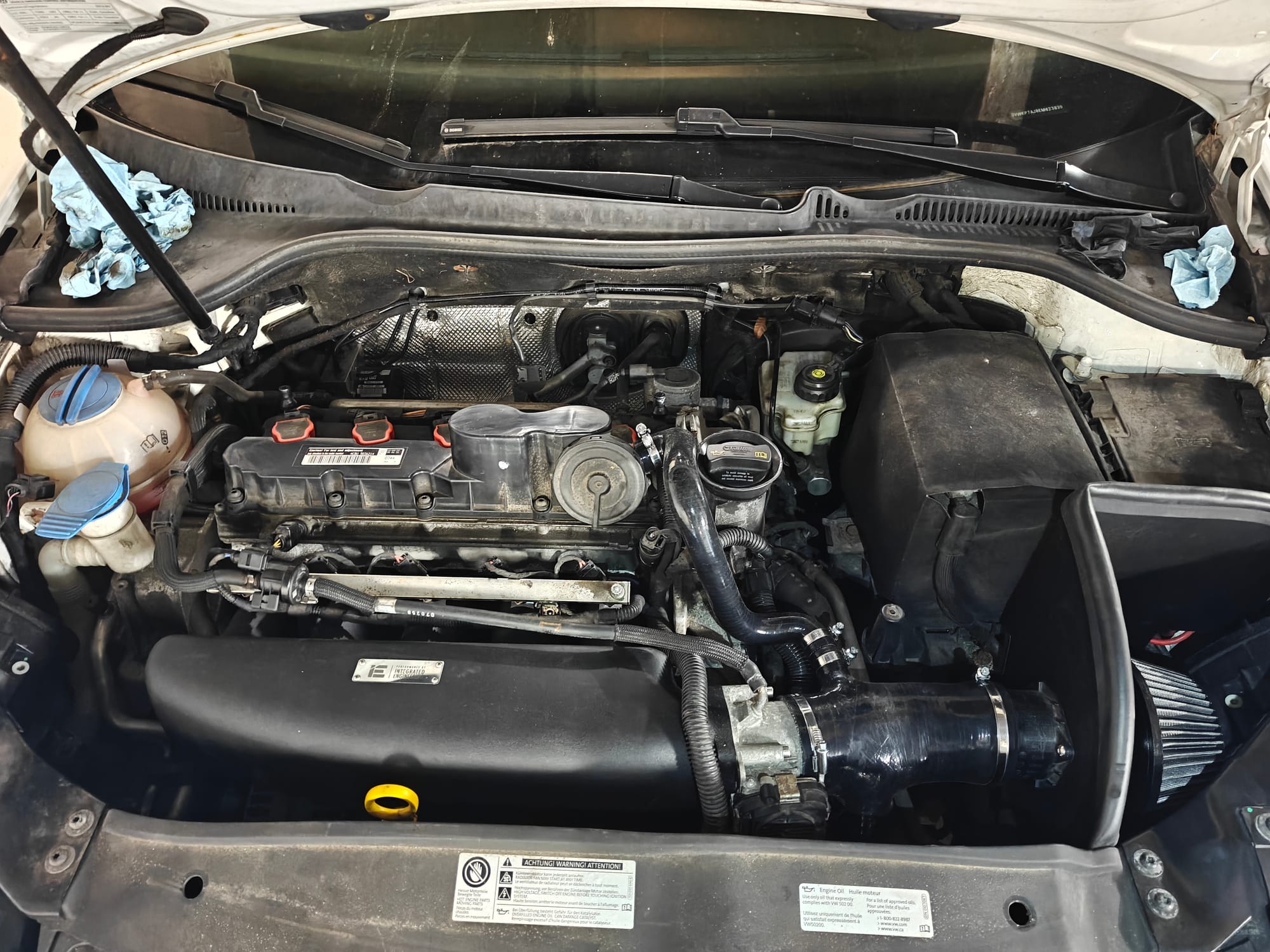

Integrated Engineering 07k intake manifold

As with many people during the lock-down period of the pandemic. We were cooped up indoors with too little to do.

My first planned escape was with my parents CR-V down to the New River Gorge which was one of the best things we could do. The higher than normal clearance, paired with AWD and ample space made it almost ideal for road tripping to climbing destinations on the east coast. It's a great car for car duty but it was far from anything enjoyable due to the lack of road feel and power.

When I returned the car back to my parents I was on the search for a car I could drive to climbing places with ample space to sleep in. I REALLY wanted a Mazda 5 of any generation. They were basically mini-minivans but almost as nimble and fun as a Mazda 3. I test drove a few but they were all very high mileage examples with more rust than I was comfortable dealing with.

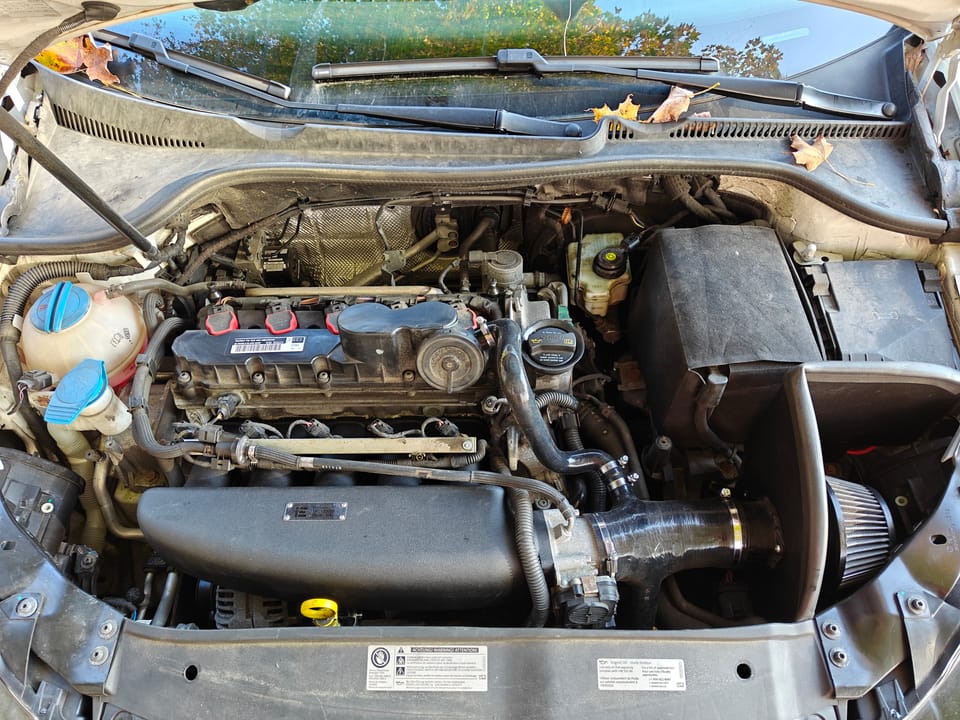

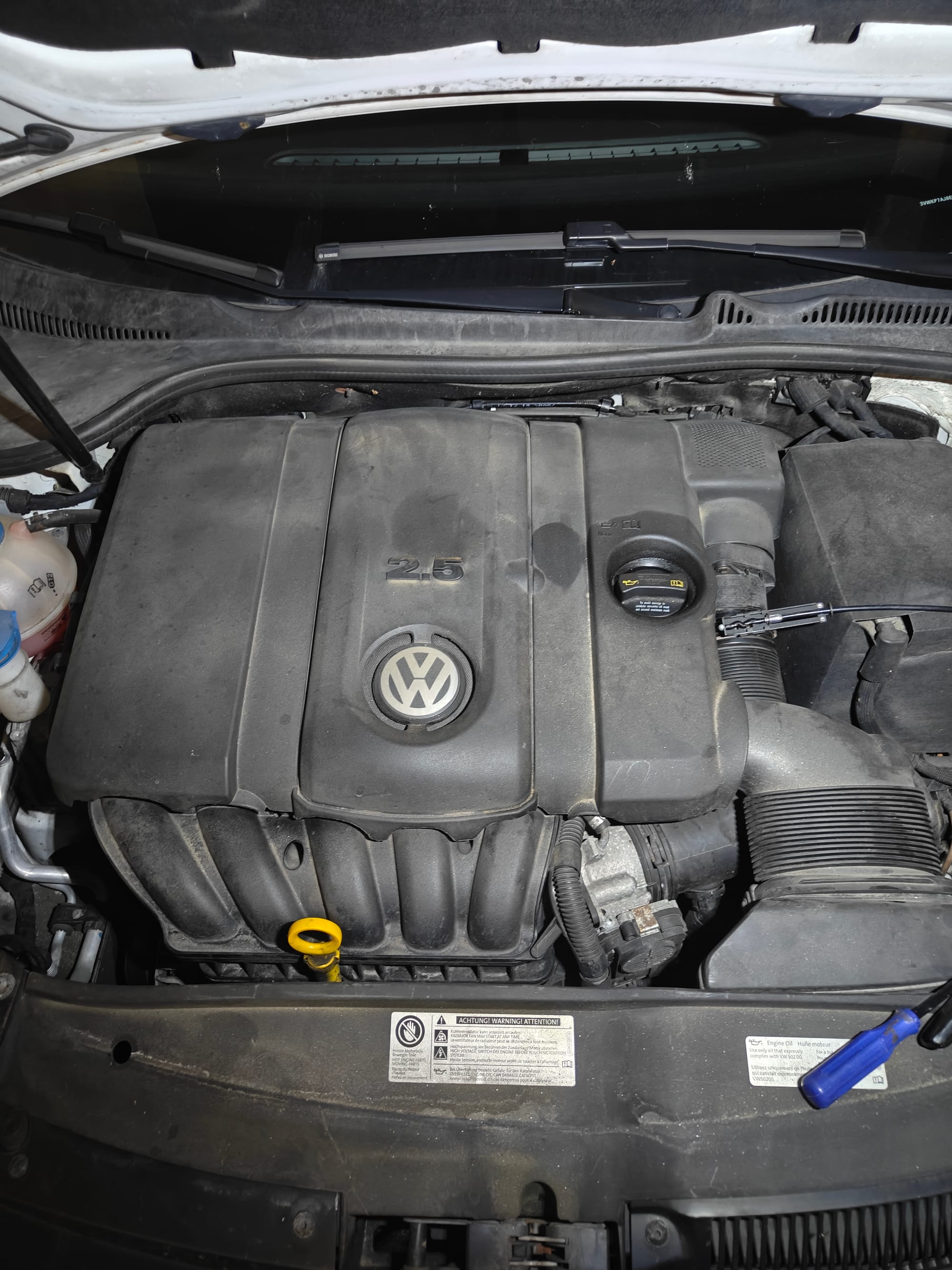

Somehow, I got "lucky" and this manual 5 cylinder wagon popped up in my searches. I researched it the engine and model and test drove it and ended up with it not too long after. I prepped it for a 1000 mile drive to the New and back and did it without complaining. The clearance wasn't as high as the CR-V so I shielded the oil pan with this ECS tuning aluminum plate. The car also lacked any form of power so I purchased the Integrated Engineering Power kit which sat on my shelf for 4 years because I simply didn't have time to put it in and have the car functional for each weekend trip up to Rumney.

During those 4 years, I've replaced the seats, like 3 times, put on two different roof boxes, purchased 3 sets of wheels and tires and replaced the suspension. I also bought a windows laptop so that I could tune the car once I installed the power kit and sold it because I never used it.

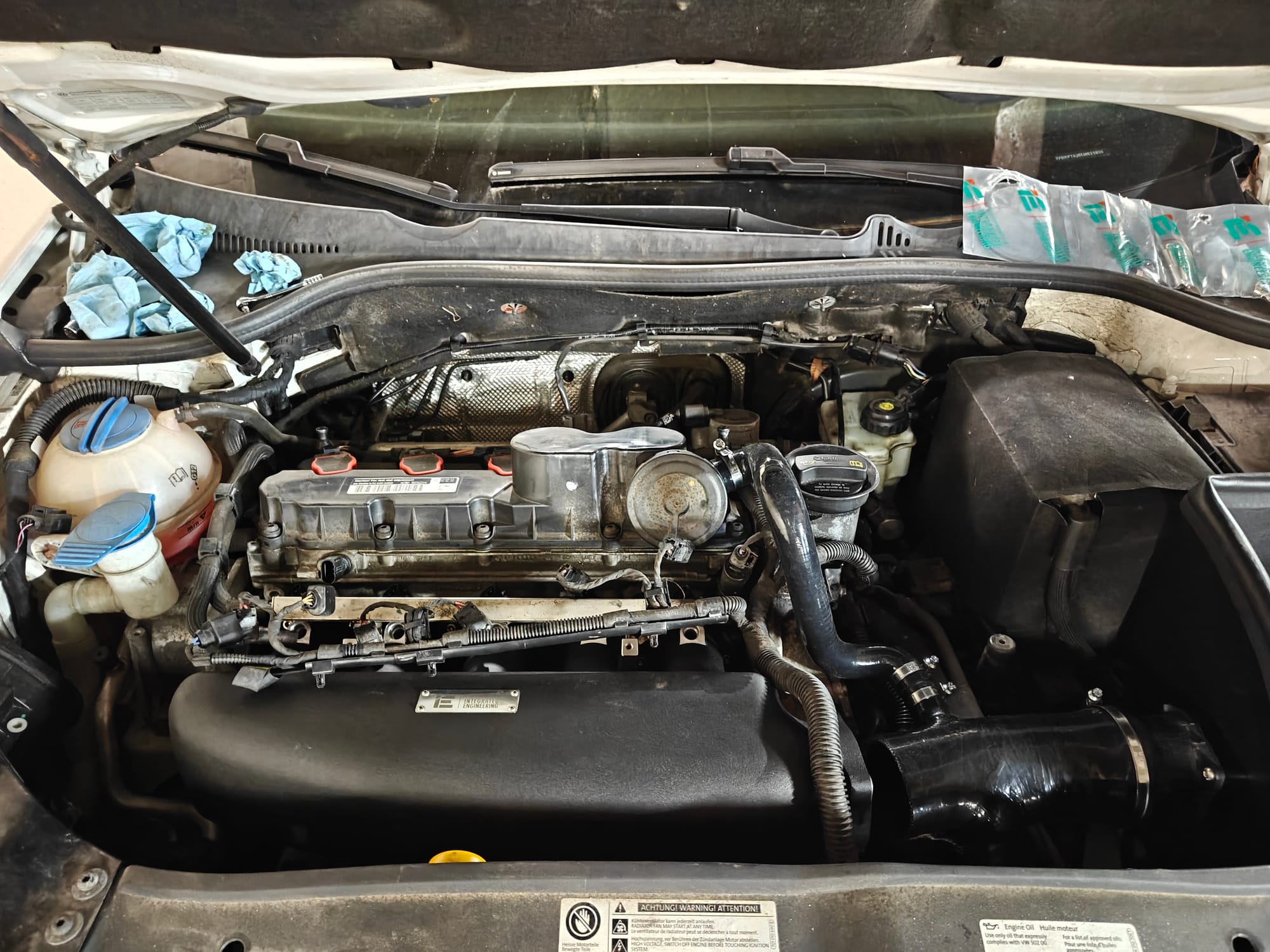

I watched a few install videos several times and read through the manual several times. Neither of these things mentioned some things that made my life absolutely miserable.

- VW uses triple square bolts for stuff attached to the engine. I had to buy these bits. But also, some of them needed to be a certain dimension so that they'd fit.

- There were 2 bolts that held the engine hoist / wire holder onto the block. The clearance required that I had to buy a low profile bit that'd fit in the space necessary to get in there.

- The bolts that held the intake manifold onto the engine required an extra extra long 6mm hex bit or a 1/4" socket attached to a 12" long extension. I bought a bunch of different sizes because I kept finding that I needed something longer to get to the bolts and that only a 1/4" socket would fit.

- Extra extra long extension to get to the two bolts underneath the intake manifold.

- Tiny 5mm hex wrench for one single bolt underneath the center runner. This made me so angry that I almost rage sold my car.

It took several days to remove the original intake manifold because I kept trial and error buying tools. With all the things off, I began piecing things together and I quickly learned I was missing a tube that connected the PCV to the intake. An email to Integrated Engineering and 2 weeks later, I got that part. I had started installing all the other things though in the meantime.

Installing the actual manifold was a pain mainly for that one screw underneath runner 3. I had thought my racheting 5mm wrench would be game changer BUT it didn't fit! I was so mad and had to turn that bolt to tight 3 degrees at a time. My hand and arm cramped a million times.

When it was time to install the throttle body, there was simply no space. I tried to get it on the intake hose and on the manifold at the same time but that didn't work. The O ring on the manifold kept falling off. I lost it. I ended up taking off the MAF spacer to make space and only then did things come together.

Last few notes:

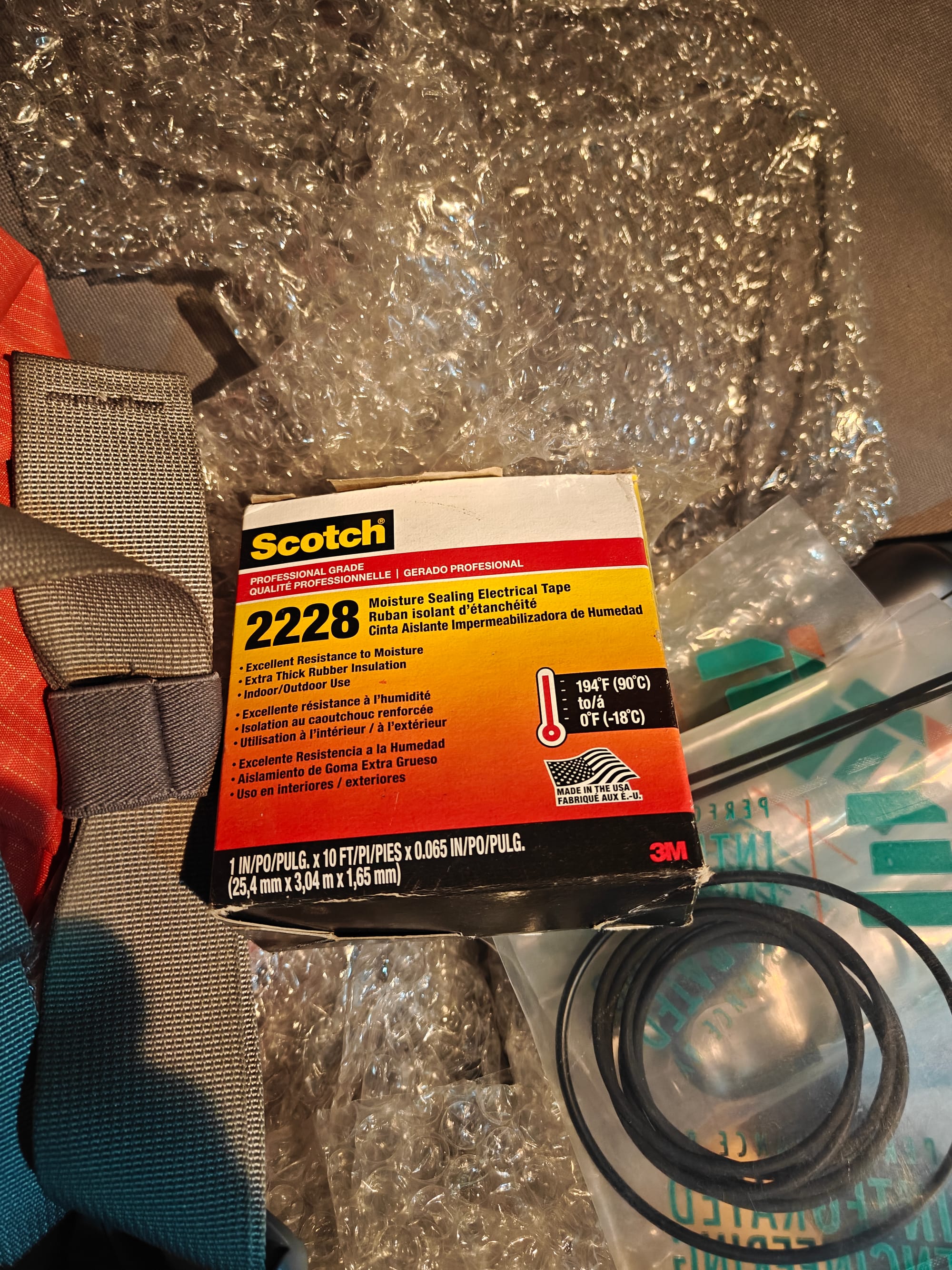

- The heat shield is relatively sharp and rubs against a lot of stuff. Having some 3m electrical tape wrapped around the edges made me feel much better.

- The heat shield bolt doesn't line up with the original hole at the front of the car. I had to ziptie it on to keep it from rubbing against the radiator.

- you will need some extra tube clamps

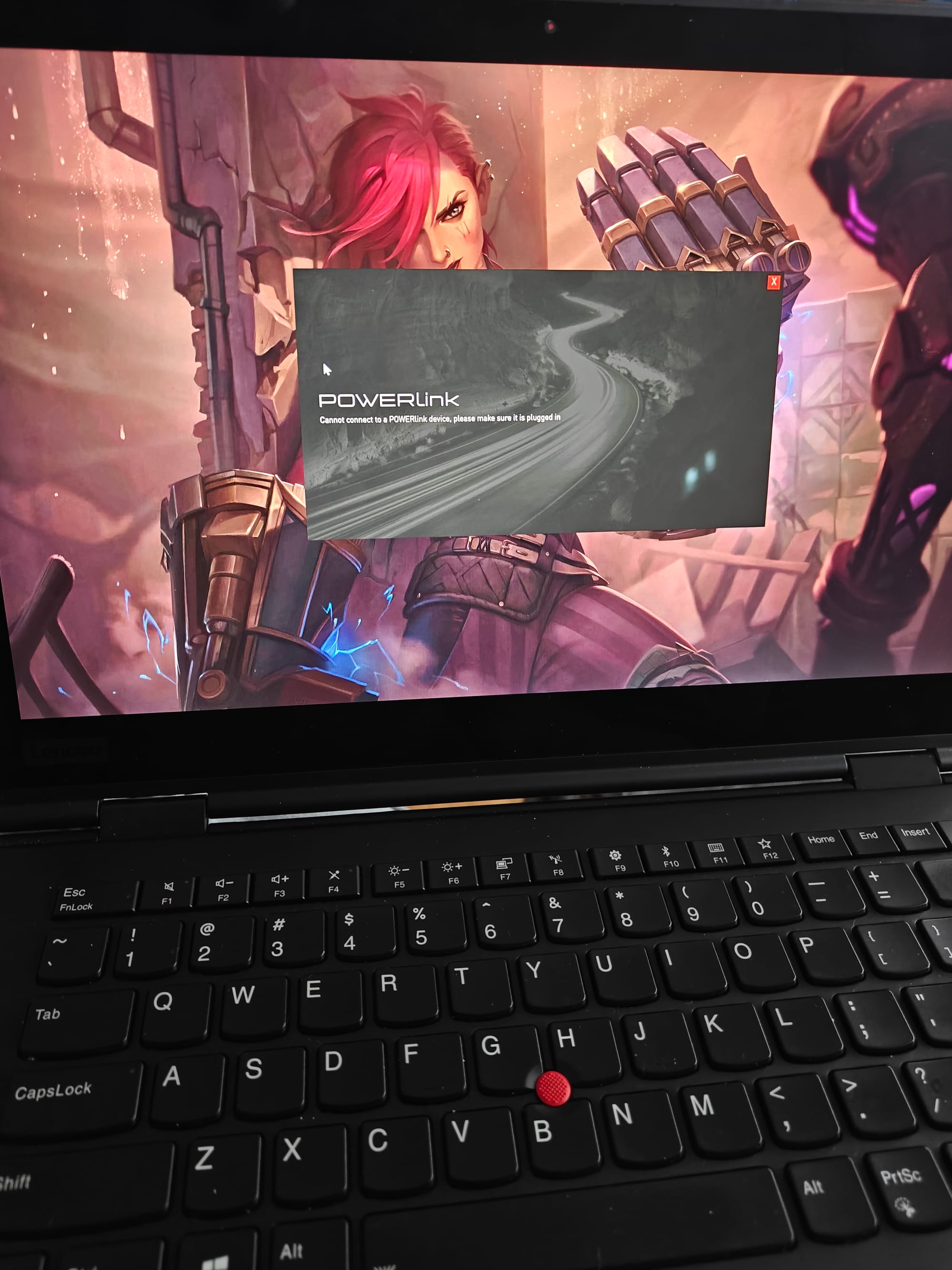

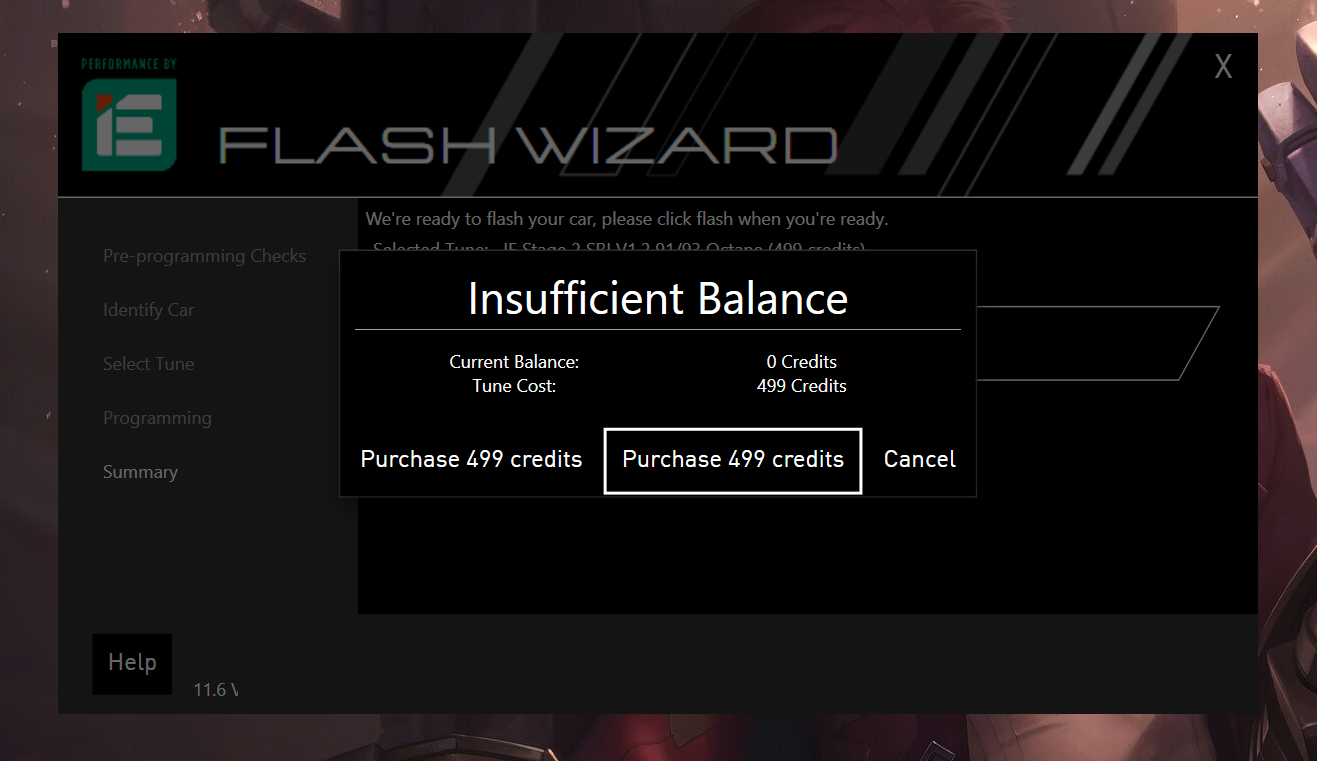

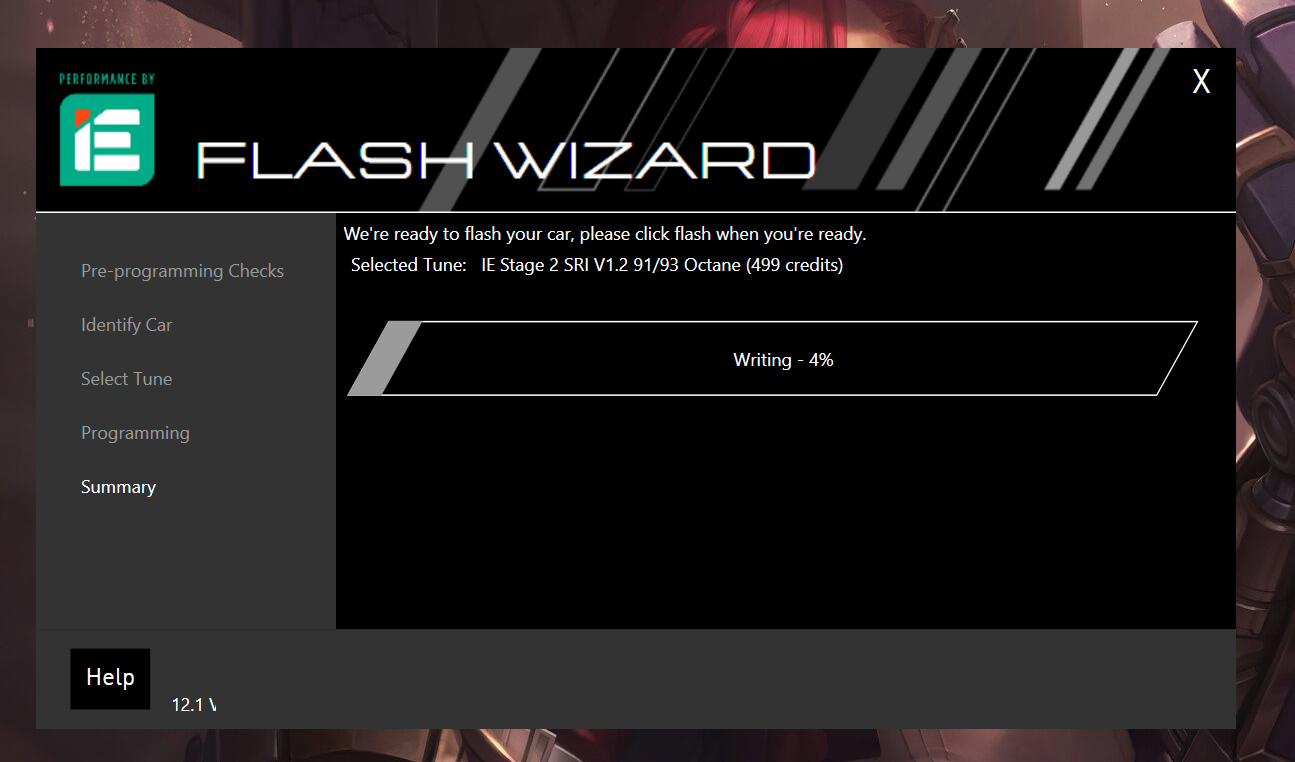

The car was operational again after 3 weeks and the only thing left was to get it tuned. Integrated Engineering included a tuning module with the kit but it only worked with a machine running Windows. I sadly don't have a Windows machine anymore and installing it in a VM on my linux laptop yielded nothing useful. I went to purchase a used laptop off Facebook marketplace. However, the tuning software didn't work with the tuning cable. So I bought another windows PC from ebay and it didn't on that either which led me to RMA'ing the device with Integrated Engineering.

Tuning the car was sort of scary. It had me turn the car on and off a couple times during the tuning process.

Overall, the new manifold made my engine bay look much better and I can hear louder induction noises but it doesn't have the original harmonized 5 cylinder sound as before. While Integrated Engineering's tech support has been okay, they're slow with even slower shipping.

The car doesn't have crazy rev hang anymore (for emissions and possibly to get into gear more easily) and getting into first from a stop is extra buttery smooth. Gas mileage suffered but it might be worth it? Time will tell but so far, that $1500 kit sitting on my shelf is now doing something on the car.